Modern software is key to providing reliable service

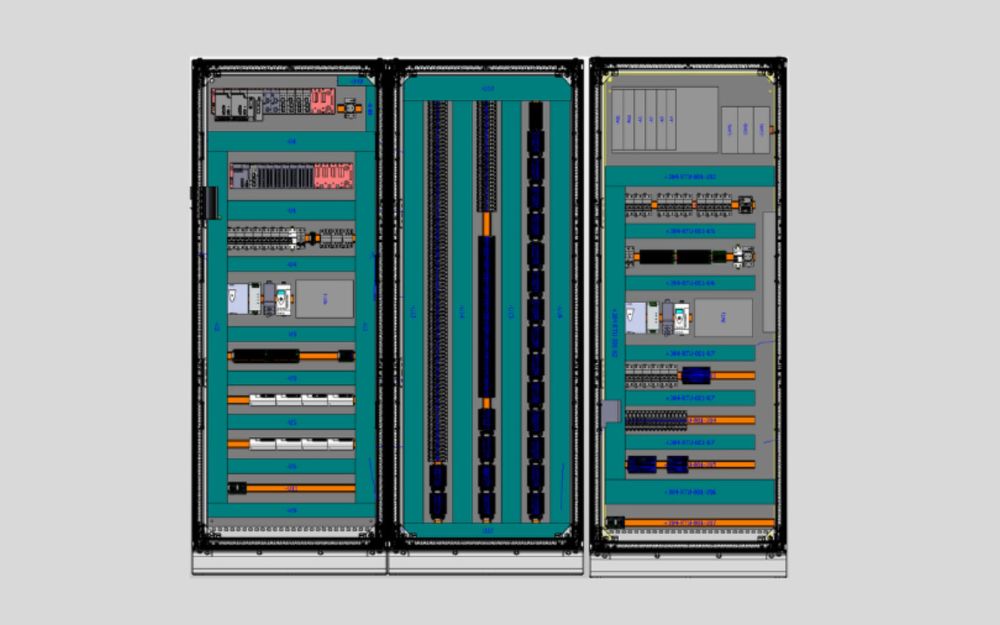

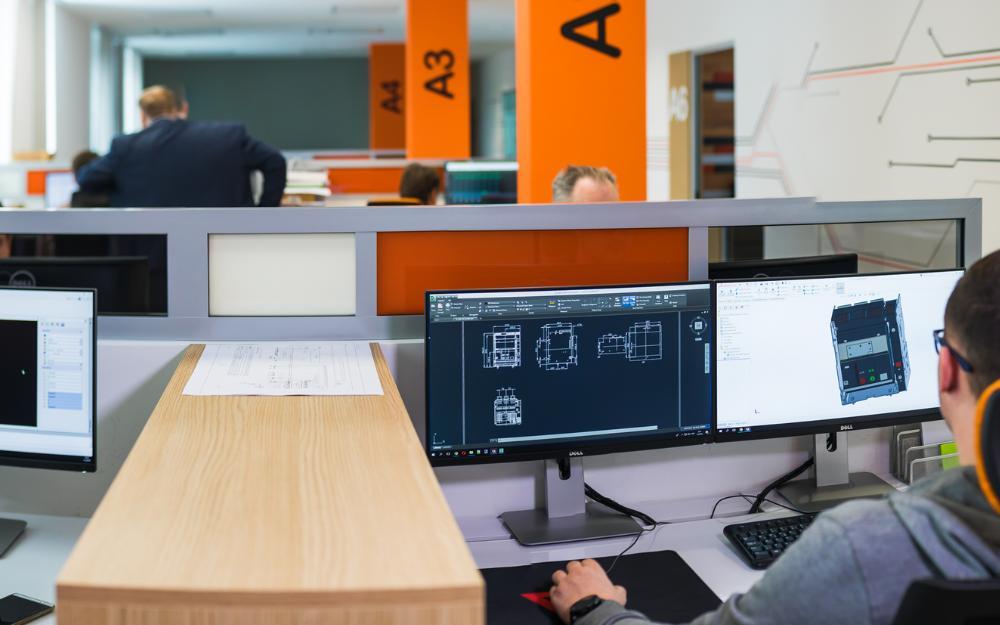

To provide reliable design & assembly service to our customers, our team of engineers and designers specialized in using different software. Among others, for the design and schematics of electrical cabinets, we are using EPLAN.

We use it to create accurate and detailed designs for a wide variety of projects. It allows our team of engineers, designers, and technicians to create and visualize complex systems in three dimensions, making it easier to understand how everything fits together and works, thus avoiding costly production mistakes in terms of equipment repositioning, additional drilling, and milling and rewiring.

Rich 3D library of components for competitive advantage

One of the key features of EPLAN is its extensive library of 3D models, which includes a wide range of components and equipment from various manufacturers. This allows us to quickly and easily drop in the components we need for our designs, rather than having to create them from scratch.

When manufacturer components are unavailable in the EPLANs library of 3D models, we use Solidworks to model the component and add it manually.

In addition to 3D modeling, EPLAN also includes powerful schematics design tools.

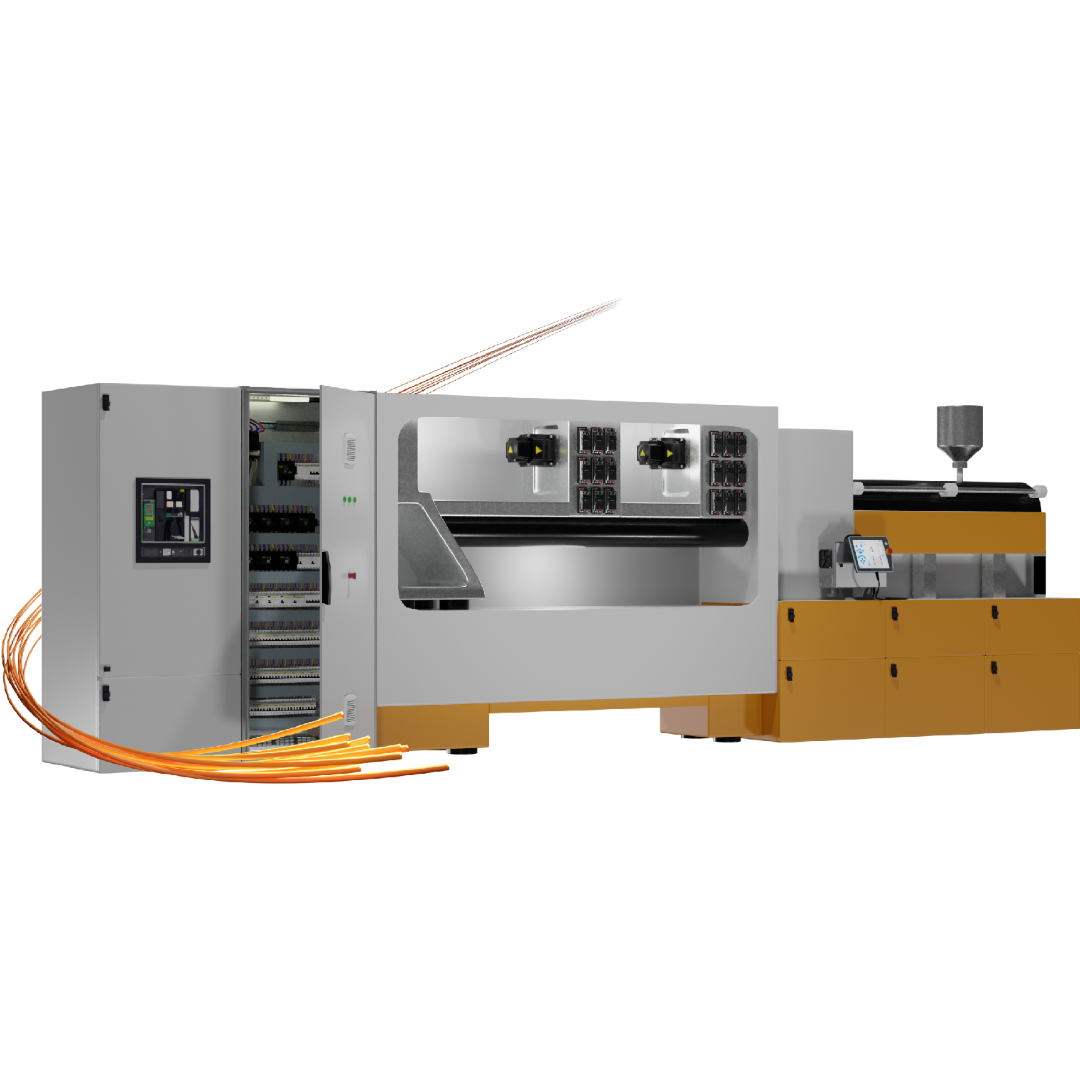

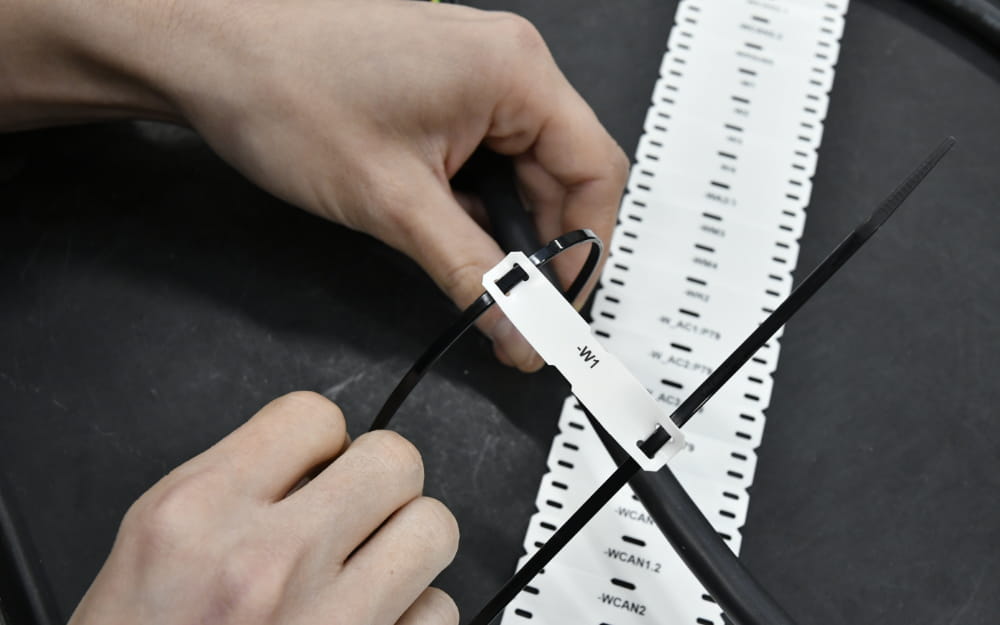

These allow us to create detailed electrical schematics complete with routing and sizing information, which is then used to push to the cloud and pull down to our production facilities where other machines such as cable and wire printing and cutting devices, CNC machines, and different printers for marking equipment are then using this data for the further production process.

This kind of digitalization and interconnectivity of key elements and project stakeholders allows us to have full control over our data, speeds up the entire process, minimizes human errors, and provides cost-effectiveness.