Increasing energy efficiency

Building construction energy savings in buildings have become an important topic in today's world where energy consumption is increasing every day.

Energy consumption in buildings can be high, but companies such as Duplico offer innovative solutions to reduce energy needs and ensure minimal consumption. In addition, increasing energy efficiency in buildings contributes to the comfort of life and durability of buildings.

The system of building and increasing energy efficiency includes several important systems, such as the physical properties of the building, heating and cooling systems, ventilation, electrical appliances and lighting.

There are many ways in which energy efficiency in buildings can be increased. For example, one of the most important aspects is building insulation, which prevents heat losses and reduces the need for heating and cooling.

In addition, the use of efficient heating, cooling and ventilation systems can also reduce the need for energy. Integrating renewable energy sources such as solar or wind energy in buildings can also reduce the need for fossil fuels.

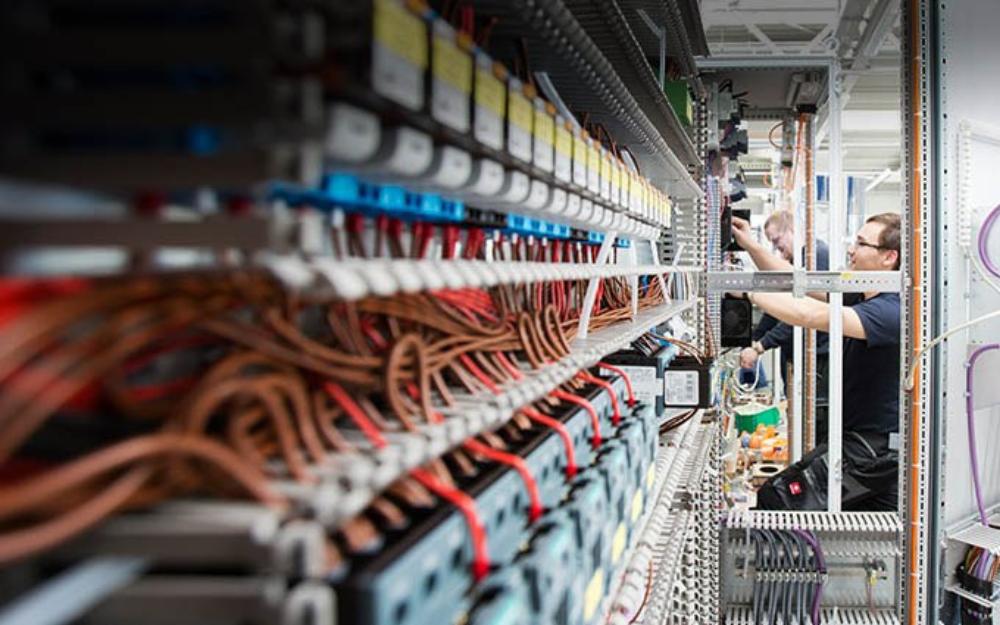

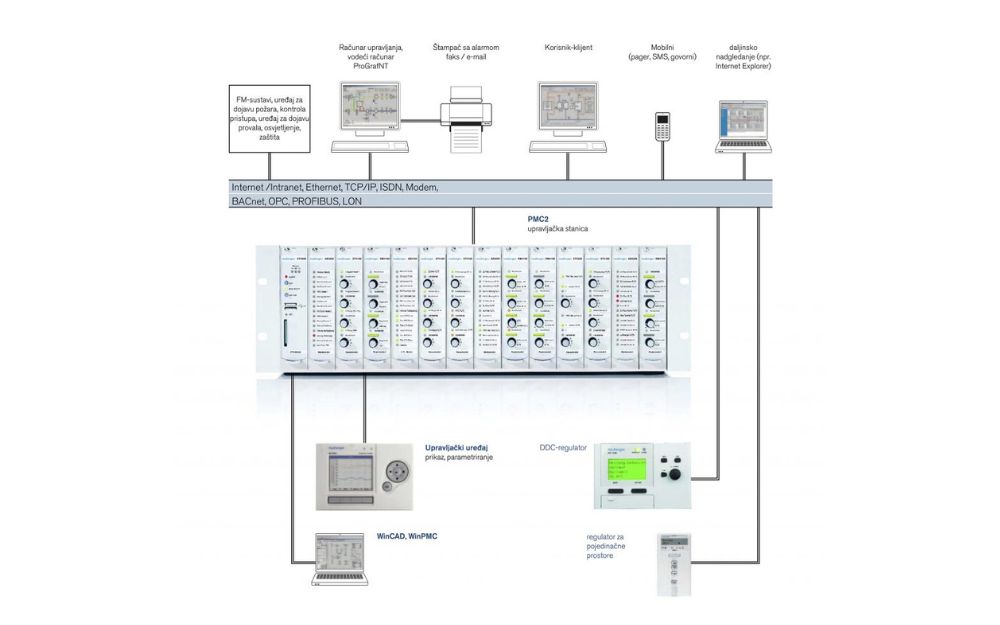

Technologies such as sensors and automatic control systems can also be very useful for increasing energy efficiency. For example, sensors can detect the presence of people in a room and adjust the temperature or lighting to reduce energy consumption. Automatic control systems can monitor energy consumption and manage all building systems to reduce energy consumption.

Duplico & energy efficiency solutions

Duplico uses its many years of experience in creating a unique system of automatic control of these systems with the aim of increasing energy efficiency. The SCADA system enables consumption monitoring and management, integration of all building energy systems and automated building heating and cooling processes, production, consumption and delivery of electricity, and lighting management.

Duplico also uses a variety of technologies to maximize the potential of solar energy and increase energy efficiency. With the help of metrics, they regulate the degree of heating and cooling of the building. Also, they use the LON communication protocol to transfer the measured values to the automatic station and control the temperature of the hot water tank.

By using Variotherm modular walls, we build an extremely economical heating and cooling system, which reduces heating costs and contributes to the energy efficiency of the building.

These innovative technologies are ideal for private and business premises, but also for public institutions such as schools, kindergartens and hospitals.

In addition to increasing energy efficiency, companies such as Duplico not only reduce energy consumption and save money, but also contribute to preserving the environment and reducing greenhouse gas emissions.